In May 2024, the company communicated with Iran's BIPC company on technologies related to oxychlorinated vinyl chloride devices and polyvinyl chloride devices.

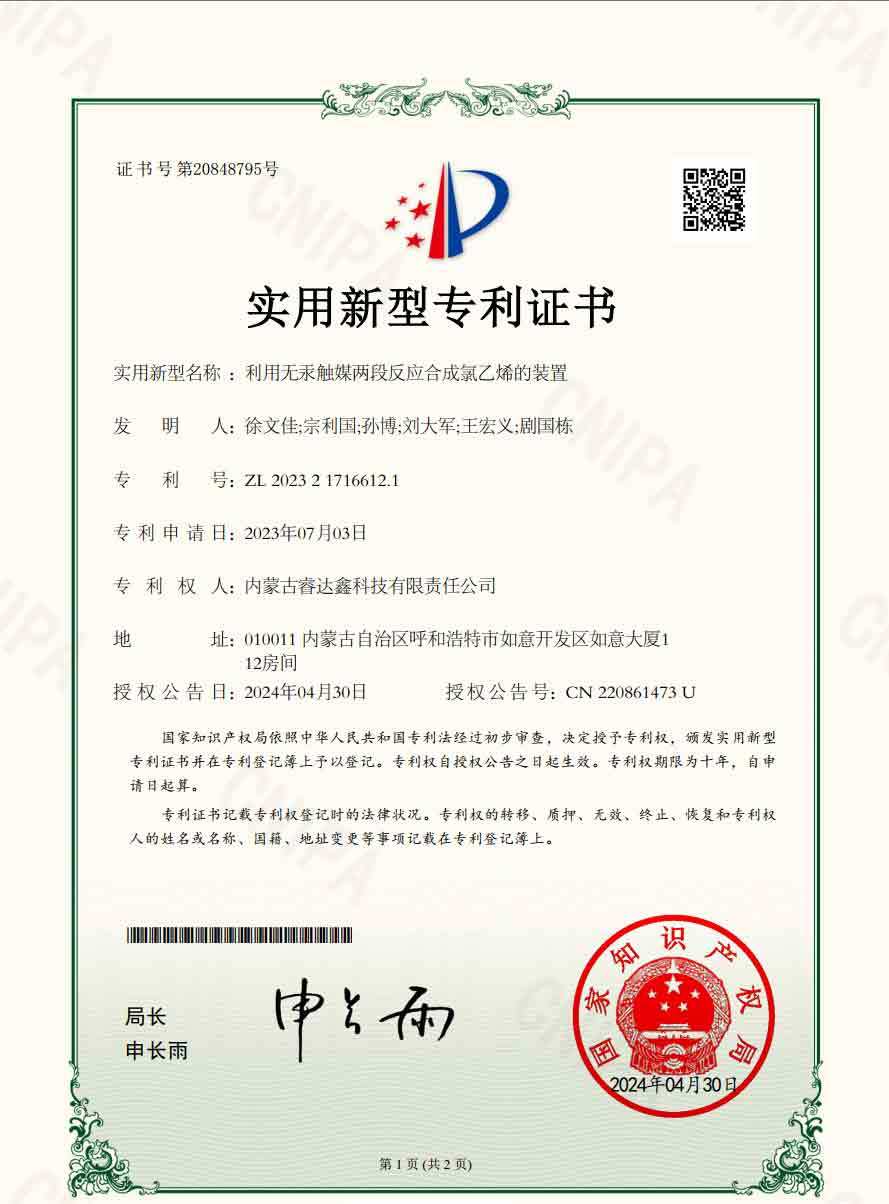

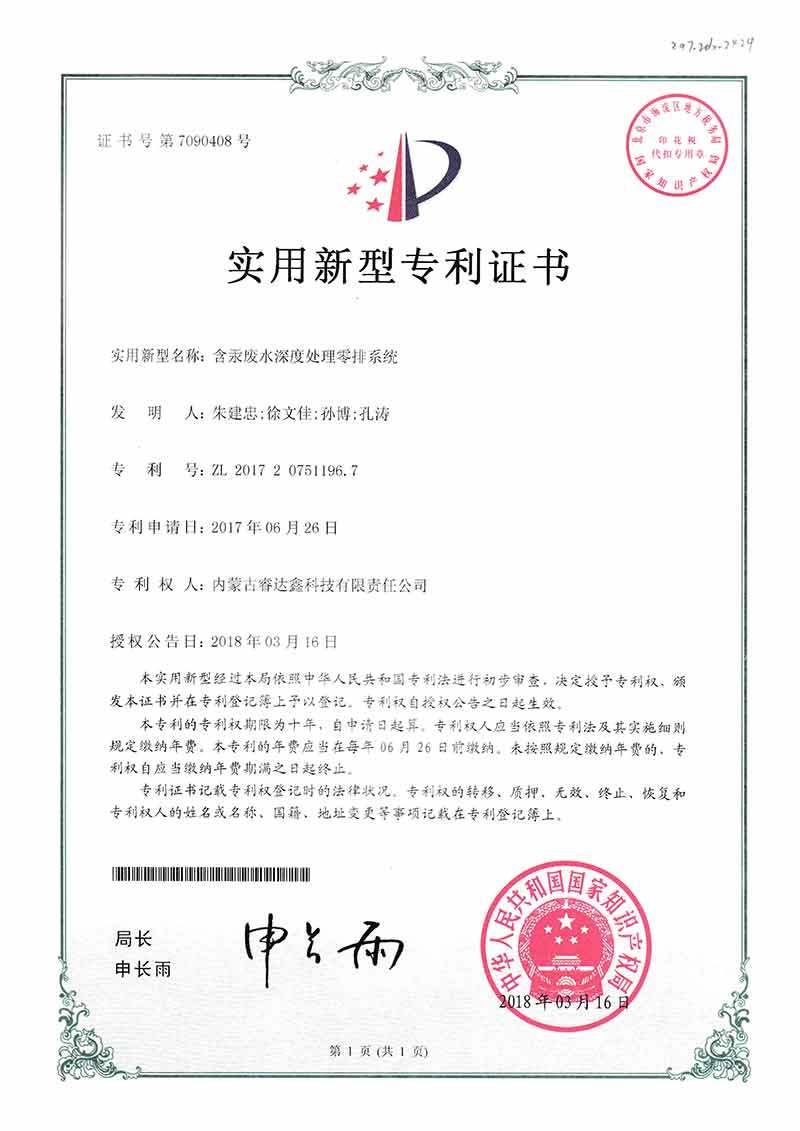

In early 2024, the company won the utility model patent for the two-stage reaction synthesis VCM process of mercury-free catalyst issued by the State Patent Office.

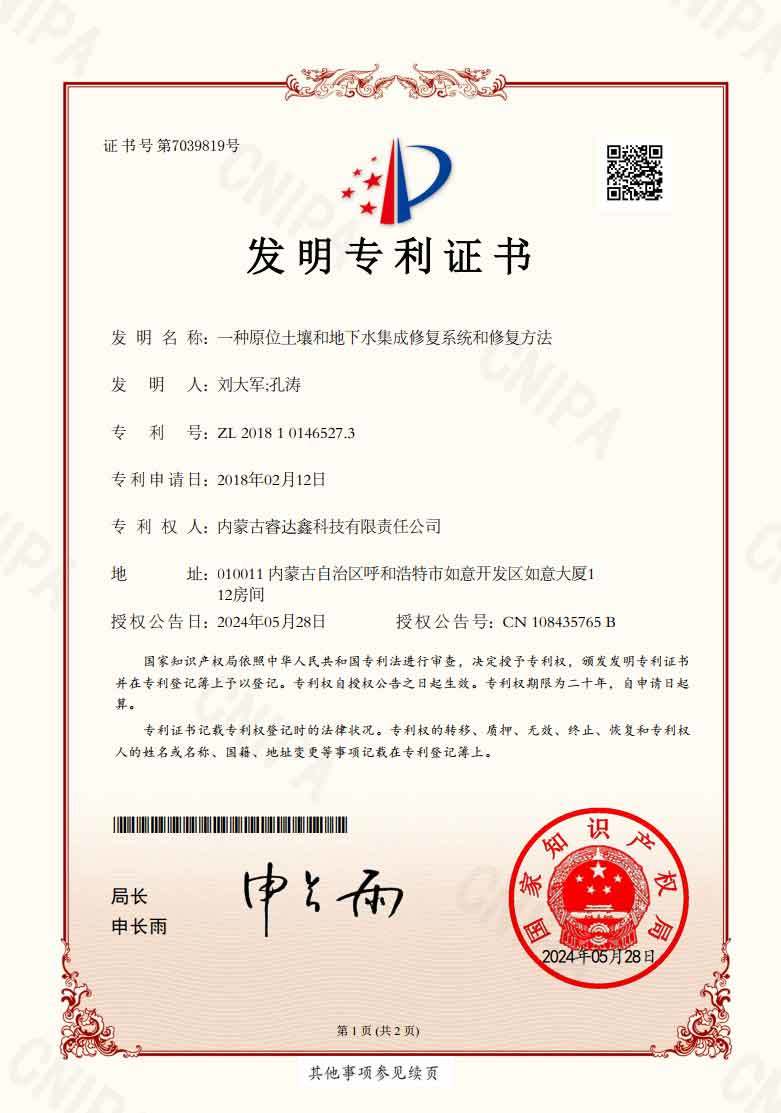

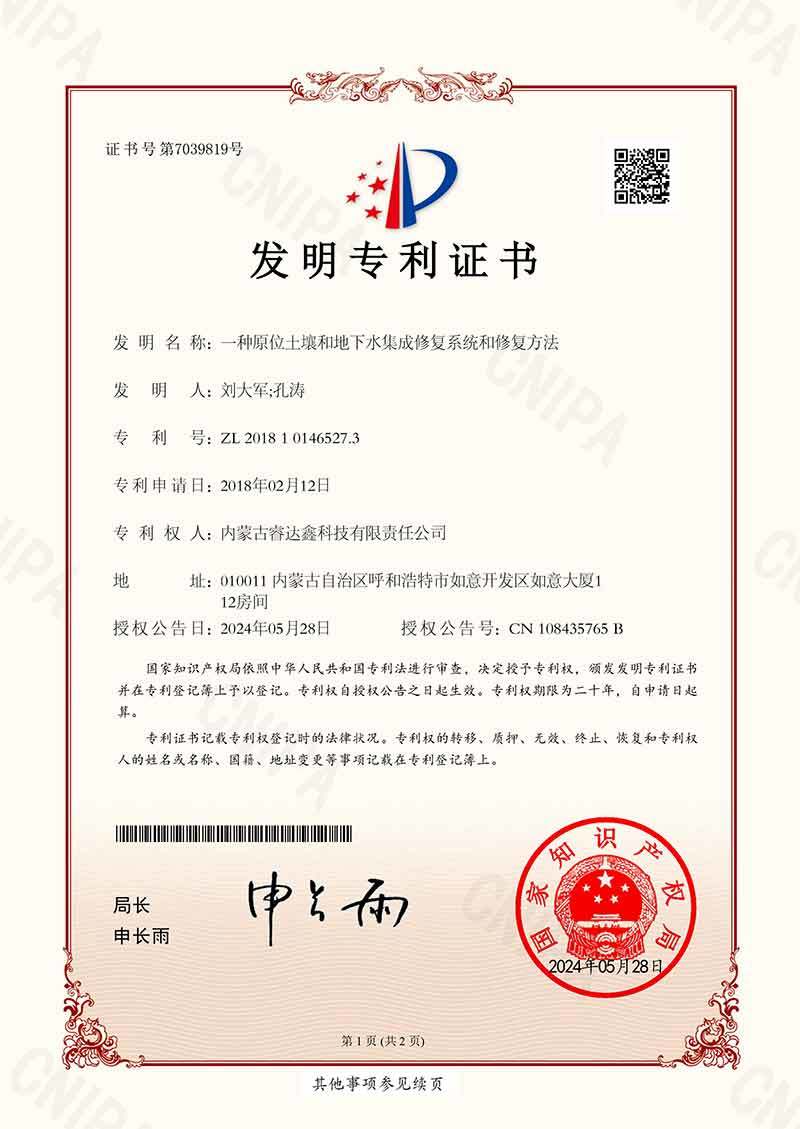

In May 2024, the company was awarded an invention patent for an in-situ soil and groundwater integrated remediation system and remediation method issued by the State Patent Office.

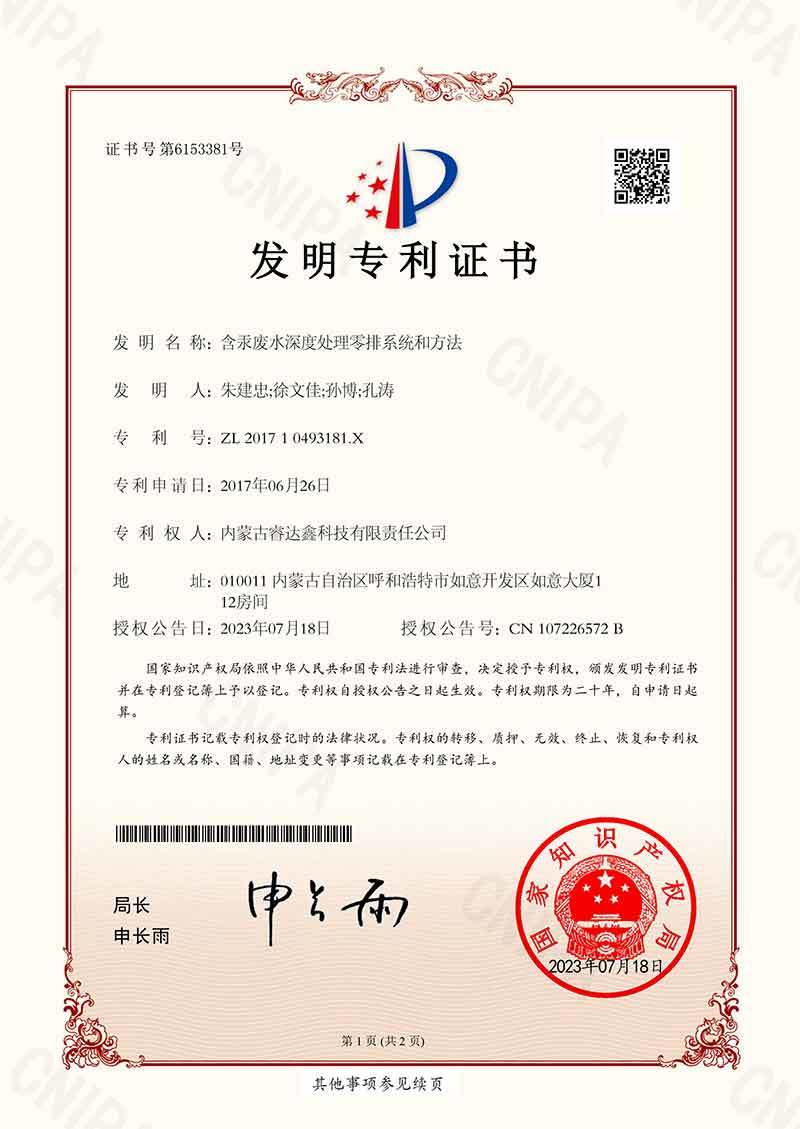

In early 2024, the company obtained a patent for the invention of a PVC organic wastewater treatment system and process issued by the State Patent Office, representing the highest level of organic wastewater treatment in the domestic PVC industry.

In January 2024, the company and Guangxi Huayi Chlor-Alkali Chemical Co., Ltd. exchanged ideas on the technical transformation of the 400000 tons/year PVC mother liquor reuse treatment device and provide the transformation plan.

About RuiDaXin

About RuiDaXin

Inner Mongolia Ruidaxin Technology Co., Ltd. was established in January 2008. It is a technology research and development enterprise established on the basis of the technology research and development center of large state-owned chemical enterprises.

With a registered capital of 8 million yuan, there are 25 employees, including 2 professor-level senior engineers and 3 senior engineers. The company's technical backbone comes from the front line of production and design, with rich theoretical and practical experience. The company has always been adhering to the concept of "customer first, leading technology", and has cooperated with Shanghai Jiaotong University, Beijing University of Chemical Technology, Beijing University of Science and Technology, Chinese Academy of Sciences and other well-known domestic institutions.

Corporate vision: Employee satisfaction, customer satisfaction

Corporate Vision: A Respected Science and Technology Innovation Enterprise in the Industry

Core values: Benefit employees, develop the enterprise, and contribute to society

Business philosophy: Creating value, win-win cooperation

On Innovation: Take the conventional to the extreme and make innovation a routine

On Service: Professional and efficient

On Quality: Quality is life

Safety concept: Safety is responsibility, safety is benefit

Transfer of technological achievements

Chemical science and technology development

Patent Display

Patent Display

Case Presentation

Case Presentation

In May 2024, the company communicated with Iran's BIPC company on technologies related to oxychlorinated vinyl chloride devices and polyvinyl chloride devices.

In May 2024, the company will communicate with Iran's BIPC company on technologies related to oxychlorinated vinyl chloride devices and polyvinyl chloride devices.

In early 2024, the company won the utility model patent for the two-stage reaction synthesis VCM process of mercury-free catalyst issued by the State Patent Office.

In early 2024, the company won the utility model patent for the two-stage reaction synthesis VCM process of mercury-free catalyst issued by the State Patent Office.

In May 2024, the company was awarded an invention patent for an in-situ soil and groundwater integrated remediation system and remediation method issued by the State Patent Office.

In May 2024, the company was awarded an invention patent for an in-situ soil and groundwater integrated remediation system and remediation method issued by the State Patent Office.

In early 2024, the company obtained a patent for the invention of a PVC organic wastewater treatment system and process issued by the State Patent Office, representing the highest level of organic wastewater treatment in the domestic PVC industry.

In early 2024, the company obtained a patent for the invention of a PVC organic wastewater treatment system and process issued by the State Patent Office, representing the highest level of organic wastewater treatment in the domestic PVC industry.